Showroom

A Sealing Machine is a device used to seal or close packages, containers, or products in a secure and airtight manner. It helps protect products from contamination, moisture, and damage during storage and transport, keeping them in optimum condition. They are designed for high-speed operation, increasing production efficiency and reducing the need for manual labor.

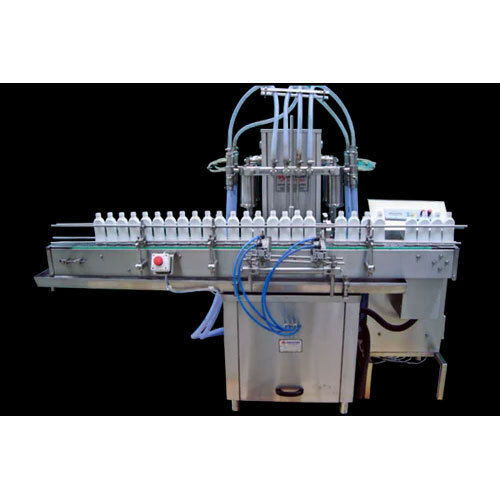

A Liquid Filling Machine is a piece of industrial equipment designed to fill containers such as bottles, cans, and pouches with liquid products. This can significantly increase production speed, reducing the time it takes to fill large quantities of containers. Their ability to enhance production speed, consistency, and quality makes them indispensable in modern manufacturing operations.

Pharmaceutical Machinery refers to the specialized equipment used in the pharmaceutical industry to manufacture, process, package, and inspect pharmaceutical products. These are automated to ensure speed, consistency, and reduced human error in large-scale manufacturing processes. They are easy to clean, sanitize, and maintain to prevent contamination, ensuring the sterility and safety of the final product.

Tablet Packing Machine is an essential piece of equipment in the pharmaceutical industry that is designed to automatically pack tablets into various types of packaging, such as blister packs, bottles, cartons, or pouches. These machines ensure that each package contains the correct number of tablets, with high precision and minimal error.

Bottle Rinsing Filling Capping Machine is widely used in high-volume production lines to streamline the bottling process and ensure product quality, safety, and efficiency. It automates the tasks of cleaning, filling, and capping bottles with minimal human intervention, leading to high-speed production, cost-efficiency, and consistent product quality. Their integrated design allows for a streamlined packaging process, ensuring that products are safely packed and ready for distribution.

Manual Paste Filling Machine is designed to handle thick, viscous pastes such as sauces, creams, and pharmaceutical ointments. Though suitable for smaller operations, these machines are versatile, requiring minimal maintenance and offering excellent flexibility in terms of container size and product type. These machines have a relatively simple construction, often consisting of a filling chamber, nozzle, piston, and container holder.

An Automatic Bottle Labeling Machine is a highly efficient and precise piece of equipment designed to automate the process of labeling bottles in various industries, including food and beverage, pharmaceuticals, cosmetics, and household products. They can handle various bottle types, sizes, and shapes, making them adaptable for different industries and products. These machines significantly reduce the need for manual labor, lowering production costs and improving overall efficiency in the manufacturing process.

An Inspection Conveyor is a specialized conveyor system used in various industries to transport products through an inspection process. They are commonly used in food and beverage, pharmaceuticals, electronics, manufacturing, and packaging industries to ensure that only products that meet quality standards move forward. These conveyors ensure consistent inspection standards across all products, reducing human error that can occur in manual inspections.

A Screen Printing Machine is a versatile and highly efficient printing system used for applying designs, logos, or text onto a wide variety of surfaces such as textiles, ceramics, glass, plastics, metal, and paper. They are known for their long-lasting durability, making them ideal for products that will be exposed to wear, such as textile apparel, signage, and promotional items.

Rotary Turntable is a mechanical device designed to rotate products or materials in a circular motion. It is highly versatile and often integrated into automated systems for smooth material handling. This is commonly used in various industries for tasks such as assembly, inspection, packaging, or product orientation. They are especially beneficial when integrated into automated systems, where they improve the production flow and minimize the need for manual labor.

Send Inquiry

Send Inquiry Call Me Free

Call Me Free